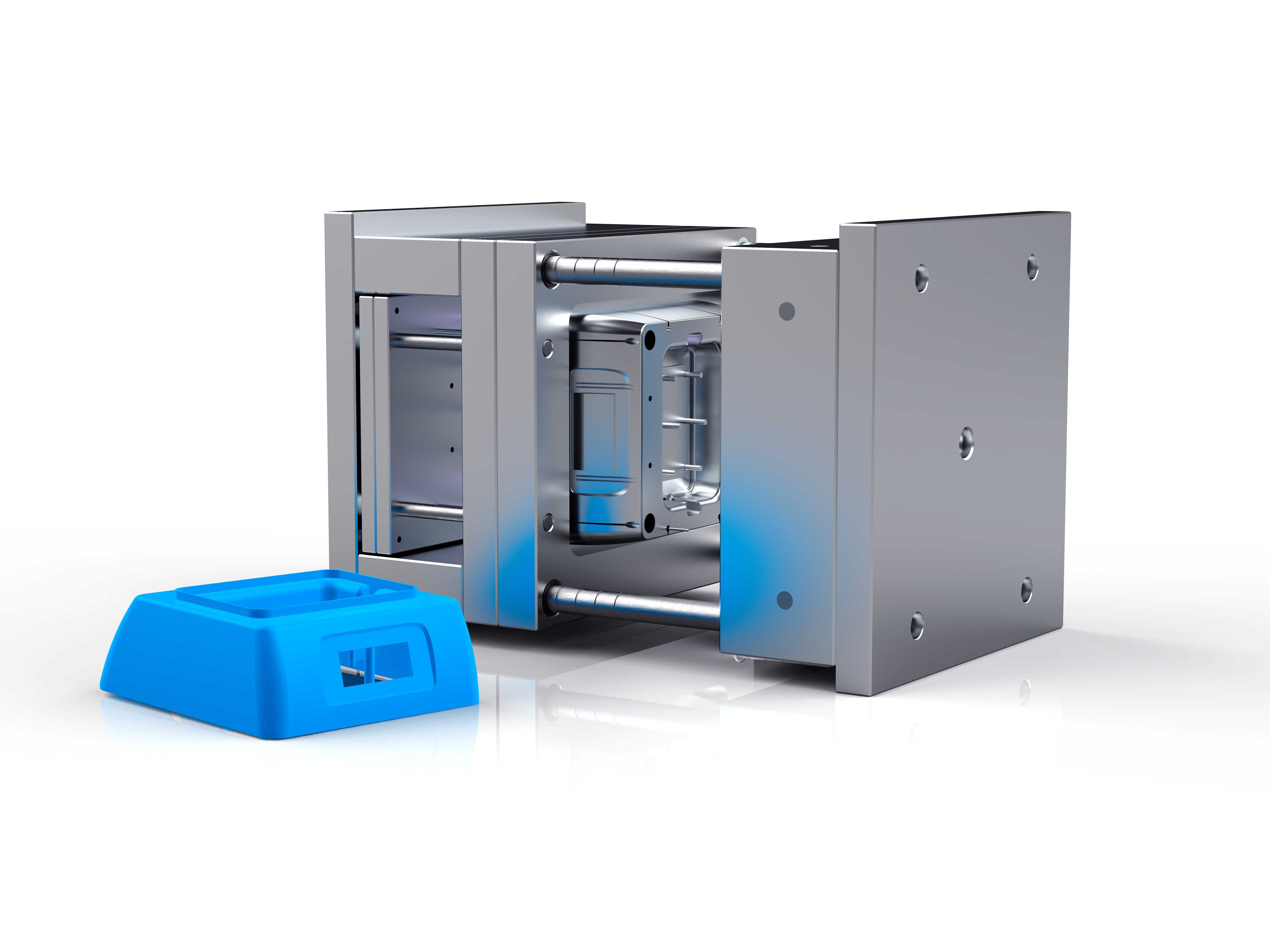

Injection Mould Design & Develop

JUFANDO innovates injection moulds and components to achieve client's specific requirements and "design for manufacture, production and cost effectiveness" in mind

We can bring your ideas to reality in areas of:

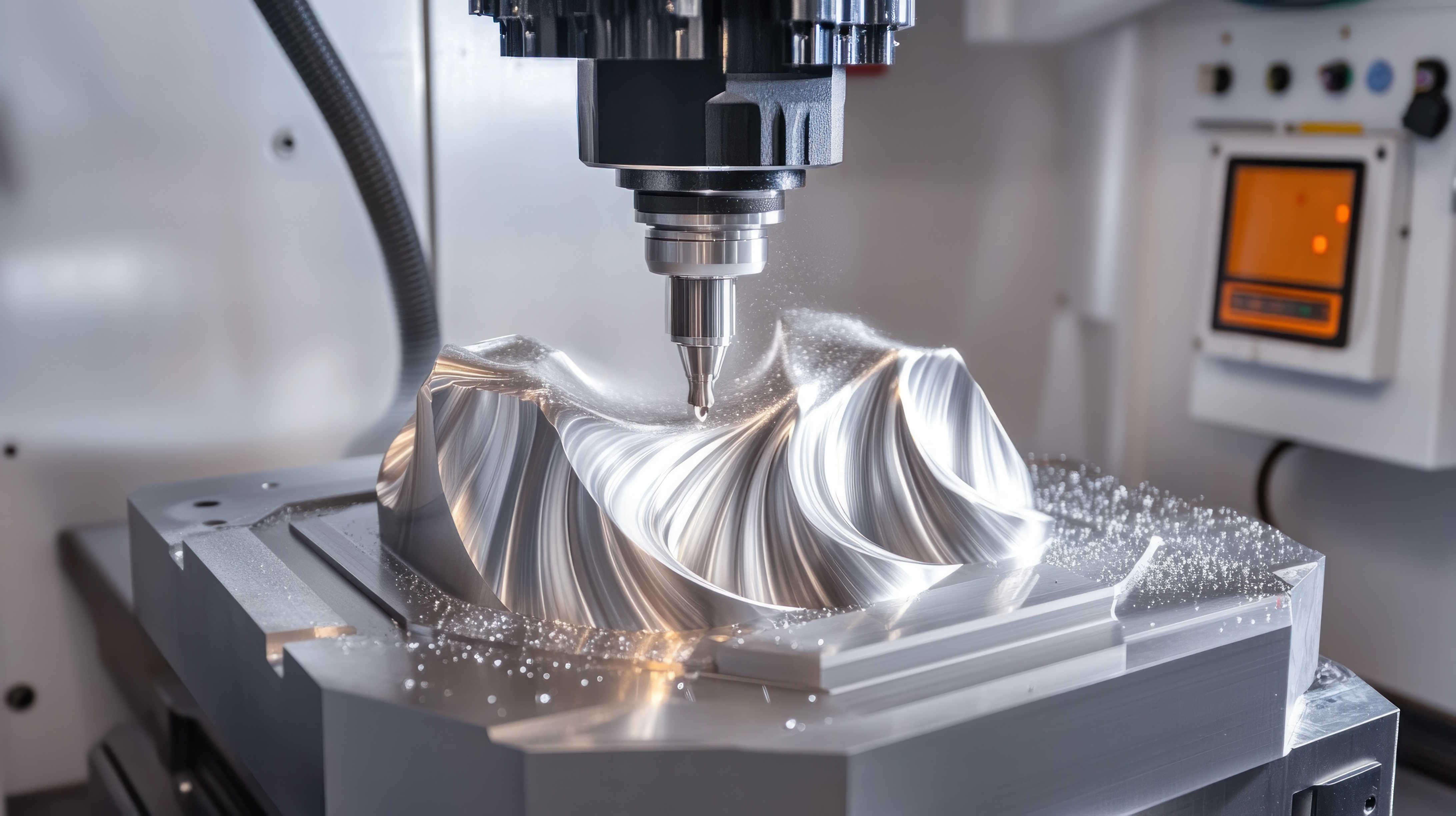

- Generic-standard moulds and tools design / development

- Speciality moulds and tools design / development (split-cavity, stripper, 3-plate, stack, hydraulic-pneumatic-gear driven, etc.)

- Auxiliary jigs and fixtures design

- EDM electrodes design

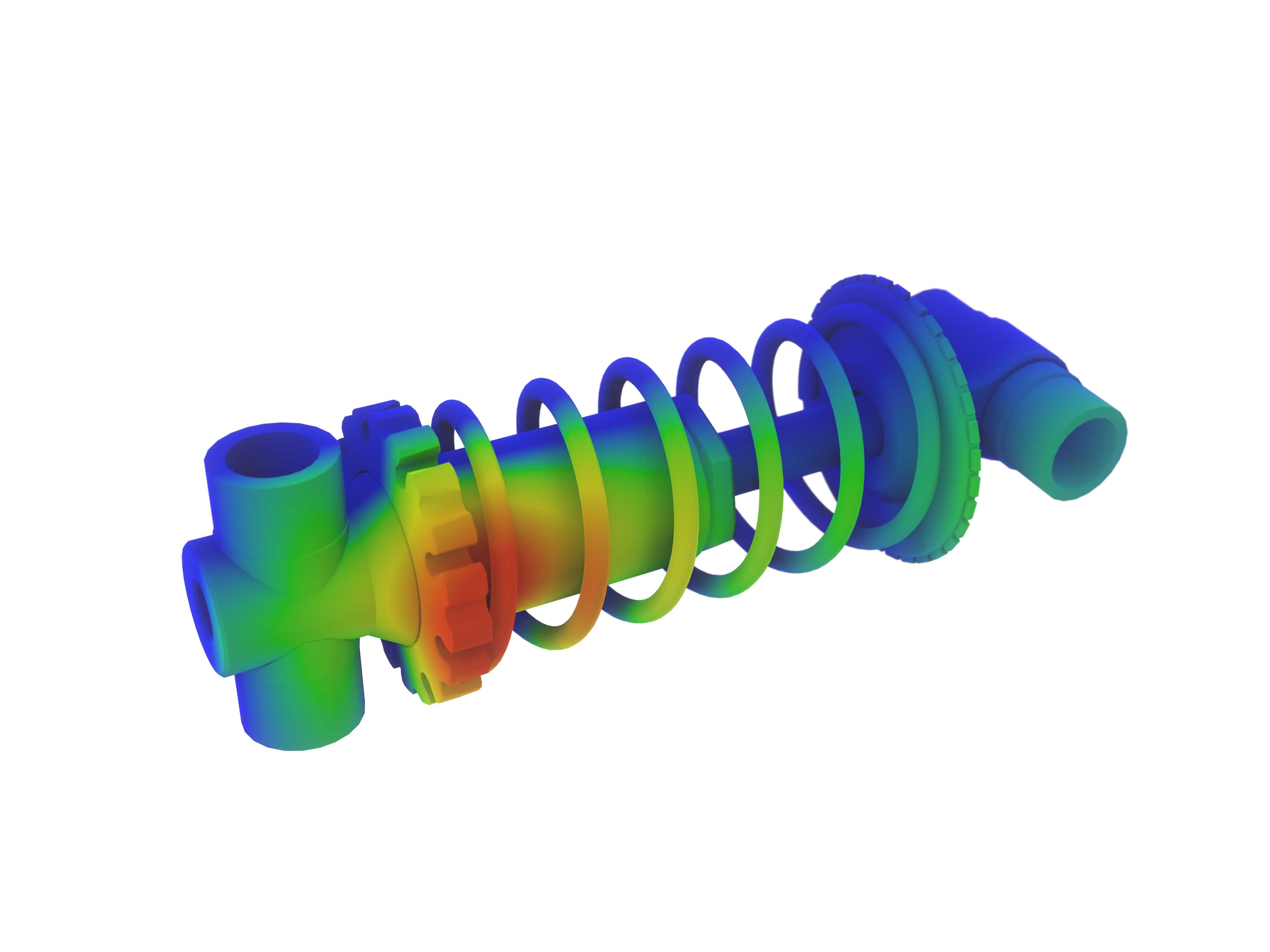

- 3D motion and melt flow analysis

- 2D/3D models, shop/manufacturing/production drawings

- G and NC codes for manufacturing

- Mould-tool manufacturing cost estimate

Creating a robust and reproducible injection mould / tool is an inventive process. This process requires listening to customer needs, consideration of life span of the tool (SPI classes 1-5), plastic material injected, precision required, injection moulding process, injection moulding machine to be used on top of efficient moulding cycle time and cost of mould manufacture.

JUFANDO design such products drawing our deep engineering expertise, years of extensive experience and innovation.

Mould design is one of the most complex design processes. Not only are the part geometries challenging, but the bad imported part features, missing drafts, impossible shut-offs and undercuts, weld lines, gate placement, shifting of cores, venting, runner system, cooling & heating, ejecting, surface quality, core metal and base as well as number of cavities can all add time and cost to mould design.

We know in and out of injection moulds and how to get a part moulded.

Do you need an injection mould / tool get designed?